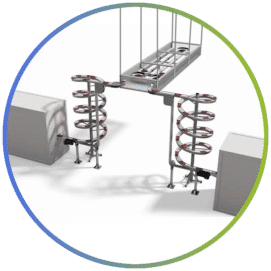

Aerial Dynamic Flow Regulator

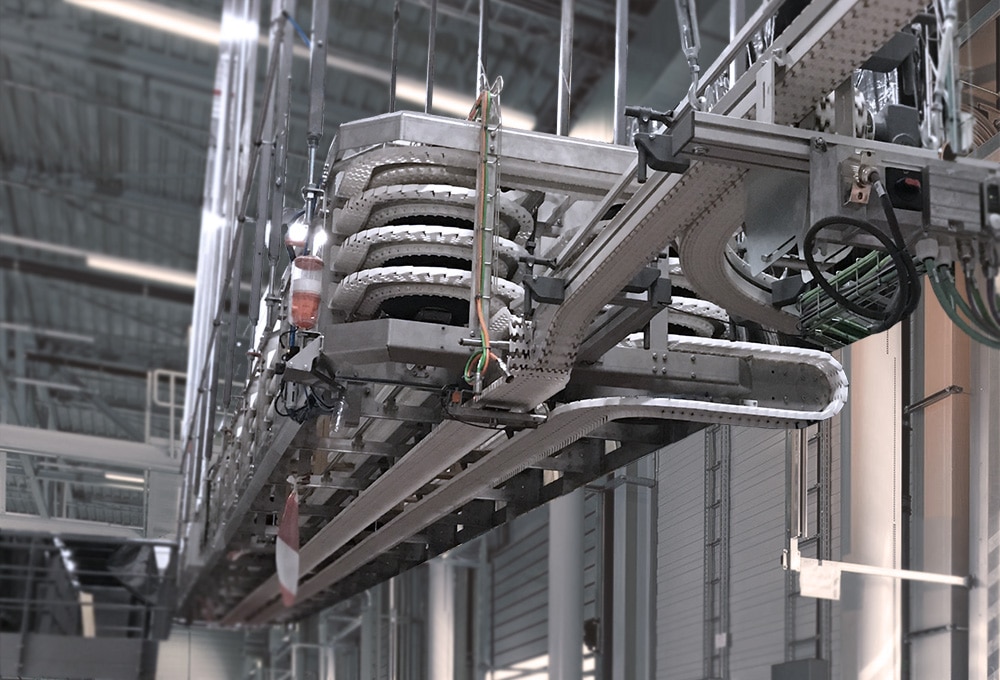

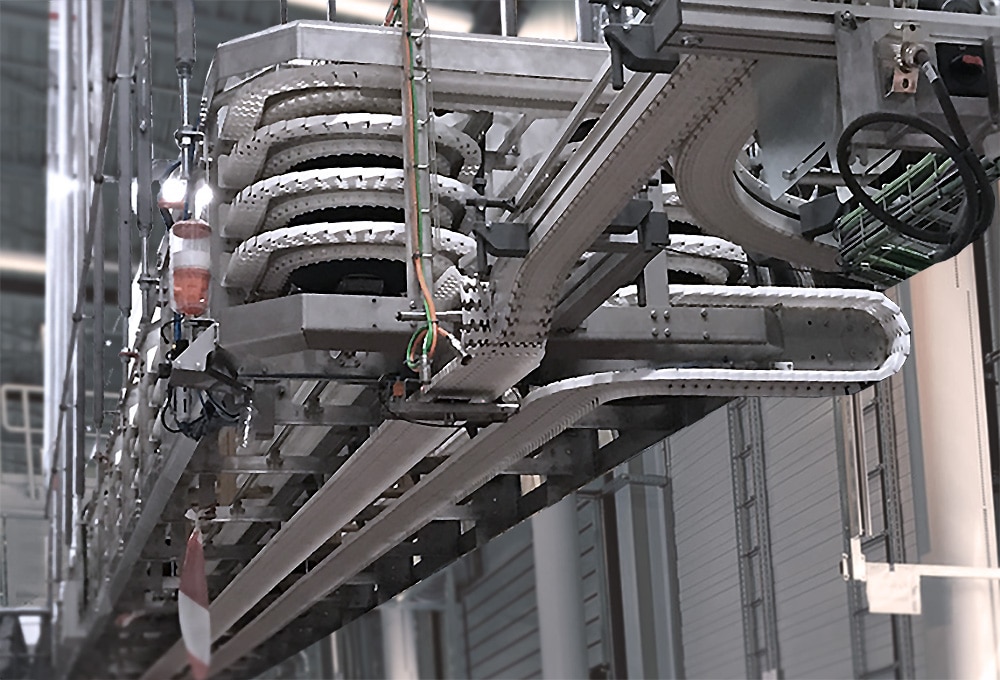

The Aerial Dynamic Flow Regulator (DFR-R) has been designed to balance the manufacturing speeds of two consecutive work stations on the same production line and, more importantly, to absorb most of the inefficiencies caused by their potential different or variable production cycles or by any short machine stops that may occur.

The DFR-R enables manufacturing lines to operate with the planned productivity and uptime thresholds as it compensates any possible machine stop with its dynamic accumulation capacity. This can be achieved by the DFR-R as it automatically accumulates products when its next downstream workstation suffers a stop and releases them back to the manufacturing line when normal working conditions are re-established. Its differential advantage is that it can be installed in height, which makes it ideal for environments where available space is scarce.

- FIFO accumulation

- Automatic and continuous accumulation

- Aerial installation (even at ceiling level)

- No intermediate transfers

- Zero pressure handling

- Increased line efficiency

- Fully configurable

- Accumulation capacity: until 400 meters

- Independent product-in and product-out speeds (up to 80 mts/min)

- Range of track shapes and sizes, up to 300 mm wide

- Maximum size of products to accumulate dependant on stability and weight

- Adaptable side guiding mechanism

- Single and continuous track with no intermediate transfers

- Product-in and product-out tracks at same or different heights

- FIFO accumulation

- Zero-pressure accumulation

- Control software fully integrated with manufacturing line

- Aerial installation (even at ceiling level)

- Accumulation capacity can be fully customized with a combination of channels and levels:

Channels x Levels 2 x 1 2 x 2 4 x 1 2 x 4 4 x 4 2 x 6 4 x 6 - Made from stainless steel

- Size: from 2m x 0,5m x 0,5m, to 50m x 1,8m x 2,5m

- Lubrication: recommended

- Power required: from 0,2 KW to 6 KW

- CE-marked

In which industries can it be used?

It can potentially be used in any industry. The limit is set by the weight and volume of the product to be transported.

What kind of products can it transport?

INPROSY solutions can transport any product below a defined maximum weight and size. For example, flowpacks, boxes, bottles, doypacks, mechanical components, canisters, electronic components…

What is the minimum size of the products to be transported?

There is no minimum size of the product to be transported. It all depends on the shape of the product and the configuration of the solution.

What is the maximum size of the products to be transported?

Depending on the shape and weight of the product, the maximum limits would be around 600x500x500 mm. For larger sizes, tailor-made solutions could be studied.

What is the minimum weight of the products to be transported?

Depending on the configuration of the solution, there would be no minimum product weight.

What is the maximum weight of the products to be transported?

Depending on the configuration of the solution, the maximum weight would be 20 kg. Tailor-made solutions could be studied for higher weights.

Is it a standard device in terms of size and capabilities, or can it be customised?

INPROSY’s range of solutions includes a line of standard products adaptable to the specific needs of each situation. In addition, INPROSY develops tailor-made solutions through its engineering department.

What is the acceptable cycle range for products to be transported?

The main factors impacting on the cycle that can be managed are the weight and shape of the product. In any case, INPROSY solutions would not be suitable for cycles resulting in conveyor speeds over 80 m/min.

Can it transport different products simultaneously?

Yes, it’s possible.

Can it connect with other devices and/or robots?

Yes, it’s possible.

Would it be modifiable in the future, if necessary?

INPROSY solutions are modular and therefore adaptable and modifiable.

What type and frequency of maintenance does it require?

INPROSY equipment is characterized by their reduced maintenance requirements.

Where can I get spare parts?

INPROSY supplies 100% of the spare parts of its solutions.

Is there technical support?

INPROSY provides technical assistance for all of its equipment.

What is the warranty period?

The warranty time of INPROSY solutions is 2 years or 4000 hours of operation.

With which interfaces is the INPROSY solutions control software compatible?

INPROSY solutions control software is compatible with most interfaces used in the industry.

Is any initial training required to operate and maintain the device?

Yes, training is included with the acquisition of any INPROSY solutions.