boxes

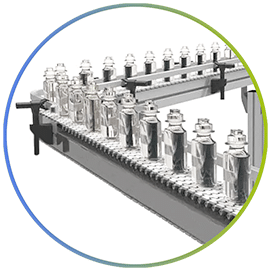

Inprosy conveyors & conveyor belts are managed by one or more electric motors (depending on the length of the conveyor and the characteristics of the products to be handled). The motors are coordinated between themselves and with the line in which they are integrated by means of programming.

The equipment provides solutions that are fully configurable to physical requirements, the available space and the input and output characteristics of products.

The Inprosy range offers a variety of surfaces in order to adapt as best as possible to the requirements and characteristics of the product to be transported, as well as to any slopes or changes of direction required.

In which industries can it be used?

It can potentially be used in any industry. The limit is set by the weight and volume of the product to be transported.

What kind of products can it transport?

INPROSY solutions can transport any product below a defined maximum weight and size. For example, flowpacks, boxes, bottles, doypacks, mechanical components, canisters, electronic components…

What is the minimum size of the products to be transported?

There is no minimum size of the product to be transported. It all depends on the shape of the product and the configuration of the solution.

What is the maximum size of the products to be transported?

Depending on the shape and weight of the product, the maximum limits would be around 600x500x500 mm. For larger sizes, tailor-made solutions could be studied.

What is the minimum weight of the products to be transported?

Depending on the configuration of the solution, there would be no minimum product weight.

What is the maximum weight of the products to be transported?

Depending on the configuration of the solution, the maximum weight would be 20 kg. Tailor-made solutions could be studied for higher weights.

Is it a standard device in terms of size and capabilities, or can it be customised?

INPROSY’s range of solutions includes a line of standard products adaptable to the specific needs of each situation. In addition, INPROSY develops tailor-made solutions through its engineering department.

What is the acceptable cycle range for products to be transported?

The main factors impacting on the cycle that can be managed are the weight and shape of the product. In any case, INPROSY solutions would not be suitable for cycles resulting in conveyor speeds over 80 m/min.

Can it transport different products simultaneously?

Yes, it’s possible.

Can it connect with other devices and/or robots?

Yes, it’s possible.

Would it be modifiable in the future, if necessary?

INPROSY solutions are modular and therefore adaptable and modifiable.

What type and frequency of maintenance does it require?

INPROSY equipment is characterized by their reduced maintenance requirements.

Where can I get spare parts?

INPROSY supplies 100% of the spare parts of its solutions.

Is there technical support?

INPROSY provides technical assistance for all of its equipment.

What is the warranty period?

The warranty time of INPROSY solutions is 2 years or 4000 hours of operation.

With which interfaces is the INPROSY solutions control software compatible?

INPROSY solutions control software is compatible with most interfaces used in the industry.

Is prior training required to operate and maintain the device?

This depends on the type of product. For complex products, training is included with the purchase of INPROSY solutions.