Long length conveyors

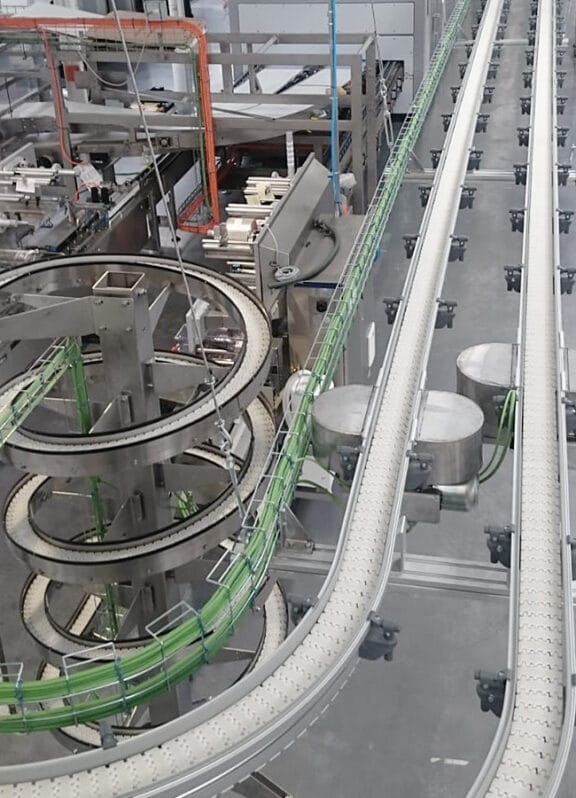

Inprosy’s long length conveyors (LLC) allow the transfer of products covering long runs continuously and without intermediate transfers.

They are adaptable to the type of product to be transported and fully configurable according to the physical conditions, the available space and the existing characteristics of product input and output interfaces.

The LLC are optimal for transporting delicate or fragile products of very different geometries, and can handle boxes, flowpacks, bags, tubes, bottles, doypacks, industrial components, etc…

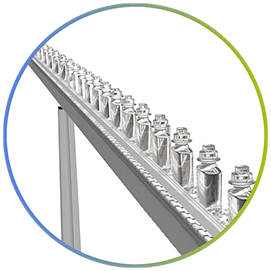

The transport is carried out on a modular chain, with links that allow the design of tracks with curves and slopes, so that they can replicate any required route.

The location of the motors that power the LLC and the coordination of their activity through their programming allow these conveyors to operate without intermediate transfers.

This minimises the risk of trapping, jamming or falling products.

- Long length transport without transfers

- Simplification of transport lines

- Reduces product trapping and falling risks

- Fully configurable

- Independent product-in and product-out speeds (up to 80 m/min)

- Continuous transport

- Range of track shapes and sizes, up to 300 mm wide

- Maximum size of products to accumulate dependant on stability and weight

- Adaptable side guiding mechanism

- Zero-pressure accumulation

- Installation at ground level or at height

- Entry and exit of products at the same height or at different levels

- Control software fully integrated with manufacturing line

- Made from stainless steel

- Power required: depending on the distance and characteristics of the circuit

- CE-marked

In which industries can it be used?

It can potentially be used in any industry. The limit is set by the weight and volume of the product to be transported.

What kind of products can it transport?

INPROSY solutions can transport any product below a defined maximum weight and size. For example, flowpacks, boxes, bottles, doypacks, mechanical components, canisters, electronic components…

What is the minimum size of the products to be transported?

There is no minimum size of the product to be transported. It all depends on the shape of the product and the configuration of the solution.

What is the maximum size of the products to be transported?

Depending on the shape and weight of the product, the maximum limits would be around 600x500x500 mm. For larger sizes, tailor-made solutions could be studied.

What is the minimum weight of the products to be transported?

Depending on the configuration of the solution, there would be no minimum product weight.

What is the maximum weight of the products to be transported?

Depending on the configuration of the solution, the maximum weight would be 20 kg. Tailor-made solutions could be studied for higher weights.

Is it a standard device in terms of size and capabilities, or can it be customised?

INPROSY’s range of solutions includes a line of standard products adaptable to the specific needs of each situation. In addition, INPROSY develops tailor-made solutions through its engineering department.

What is the acceptable cycle range for products to be transported?

The main factors impacting on the cycle that can be managed are the weight and shape of the product. In any case, INPROSY solutions would not be suitable for cycles resulting in conveyor speeds over 80 m/min.

Can it transport different products simultaneously?

Yes, it’s possible.

Can it connect with other devices and/or robots?

Yes, it’s possible.

Would it be modifiable in the future, if necessary?

INPROSY solutions are modular and therefore adaptable and modifiable.

What type and frequency of maintenance does it require?

INPROSY equipment is characterized by their reduced maintenance requirements.

Where can I get spare parts?

INPROSY supplies 100% of the spare parts of its solutions.

Is there technical support?

INPROSY provides technical assistance for all of its equipment.

What is the warranty period?

The warranty time of INPROSY solutions is 2 years or 4000 hours of operation.

With which interfaces is the INPROSY solutions control software compatible?

INPROSY solutions control software is compatible with most interfaces used in the industry.

Is any initial training required to operate and maintain the device?

Yes, training is included with the acquisition of any INPROSY solutions.