Product

Bags 200 x 150 mm.

Problem

The customer installed a new production line that operated in isolation from the rest of the factory. In this line, it produced a specialised product that used only 30% of the available capacity.

At the same time, other production lines were working at full capacity and could not fully satisfy the existing demand. These lines ended in a “bag in bag” system, in which product bags were grouped and packed within other larger bags.

In order to dedicate the available capacity of the newly installed line to support those lines operating at full capacity, it would be necessary to connect it to the “bag in bag” packing system. For that purpose, it would be critical to balance the production cycles of the various manufacturing lines with the cycle required by the “bag in bag” packaging system.

The layout of the plant was complex, with little room available and elements of the building’s structure that made it difficult to lay conveyors. In addition, the “bag in bag” packaging system was located near the roof.

Solution

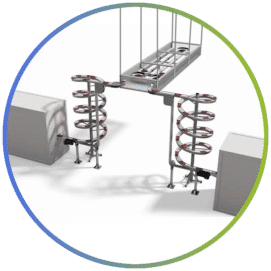

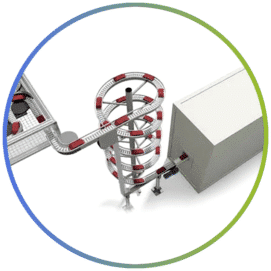

A system consisting of two Air Dynamic Flow Regulators, model DFR-R, as well as SPI-1T spirals is proposed to achieve the elevation and descent of the products. In this configuration, the main function of the DFR-R regulators is not to accumulate but to balance the cycle of products coming in with the sequence required by the “bag in bag” system. This balancing is critical to maximise the output of the packaging system.

Due to the physical complexity of the available space, a 3D point map is produced as an initial step. Once the precise calculation of the dimensions is provided by this point map, the final solution is developed and adapted.

Achieved improvements

- Achieve the balancing of lines that allows the connection between the new line and the packaging system common to all of them. This allows the new line to move to close to full capacity.

- Execute the project despite the tight and fragmented space that was restricted by numerous structural elements.

Key points

CAPACITY INCREASE – SPACE RESTRICTIONS – LINE COMBINATION – CUSTOMISED SOLUTION

* NOTE: for confidentiality reasons certain details of the project are omitted