Product

Carton box 250 x 200 x 50 mm.

Problem

The customer has installed a production line where a packing machine receives product from previous box filling machines belonging to two different lines.

To minimise the effects of any unscheduled stops experienced by the packing machine, the customer had to assign one worker per shift whose job was, in the event of any such stops, to pick the boxes coming from the box filling machines, separate them and bring them back to the line for final packing.

Additionally, the existing system did not balance the cycle of delivery of products from the box filling machines to the packing machine, which had negative effects on the efficiency of both production lines.

Solution

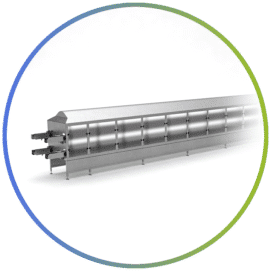

It is proposed to implement an Inprosy Multiple Dynamic Flow Regulator (DFR-ML), which comprises two devices merged into a single structure and is designed to manage the products coming from each box filling machine independently.

The proposed solution allows for the effects of any unscheduled stops by the packing machine to be absorbed automatically, through the dynamic accumulation of products for up to 3 minutes.

In addition, the coordination of control of both regulators makes it possible to balance the cycles at which products come from the previous two box filling machines and to adjust them to the needs of the subsequent packing machine.

Achieved improvements

- Elimination of manual pick-up and separation of the products whenever a stop takes place and reduction of the final production cost.

- Efficiency improvement due to the balance and regulation of the product cycle from the box filling machines to the packing machine.

Key points

DECREASE IN COSTS – FLOW REGULATION

* NOTE: for confidentiality reasons certain details of the project are omitted